BESI: Quality assurance with Deep Learning

Use of machine learning / deep learning for automated quality assurance

AI to detect defects in the manufacturing process using images

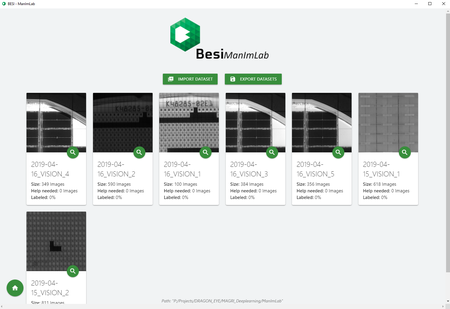

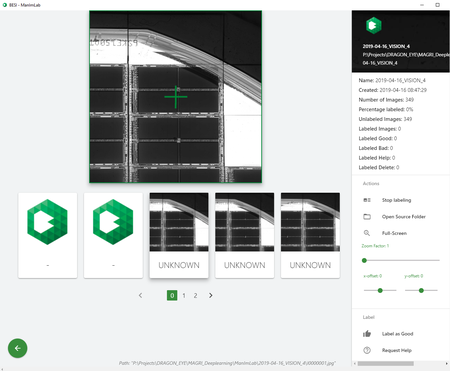

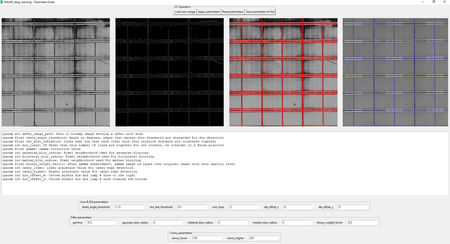

BESI, a company based in Zug, develops highly specialised manufacturing machines that are used in the production process of semiconductors. A vision system on the production machine monitors every step of the process and various algorithms ensure that each process step is carried out with the highest quality. Polygon developed and trained an AI that can recognise from an image whether the computer chip selected by the machine for assembly has damage on the edges. The computer chips can be the size of a fingernail or smaller than the diameter of a grain of rice. The AI uses a single image within milliseconds to determine whether the computer chip can be installed or must be discarded.

Machine-Learning mit Convolutional Neural Networks (CNNs)

Defect detection

Industry 4.0